Sports Field Blog

Subscribe To Email Updates

Subscribe to our weekly newsletter and we’ll send updates straight to your inbox

Greener Days Ahead! Now You Can Recycle Your Synthetic Turf Field.

It’s time to move the turf industry toward a more sustainable future, and we’ve got plans to lead the charge. Motz is working in partnership with Shaw Sports Turf, a division of Shaw Industries to offer an environmentally friendly process for the entire turf system lifecycle.

Most fields last about 10 years (with some lasting more and others less, depending on the use and maintenance of individual fields). The proper care and upkeep extends fields’ lives and requires less money and resources.

Advancing the sustainability of artificial turf sports fields

By industry estimates, about 900-1,000 fields are being replaced throughout the country annually. When you consider that each field requires the disposal of approximately 500,000 pounds (or 250 tons) of material, you can appreciate the scale of the waste being generated on an ongoing basis.

Motz is dedicated to offering innovative solutions that minimize the environmental impact of each artificial turf field system replacement and reduce the amount of waste sent to landfills. It will take coordinated efforts within the synthetic turf industry to tackle the problem in its entirety. We’re excited to announce that Shaw Industries and Motz are among the leaders in the industry making bold change.

A turnkey solution for greener synthetic turf sports fields

Let’s get specific about how we’re reducing the environmental harm of artificial fields. First, an evaluation is required of any field slated for replacement. Then, we bring equipment onsite that’s designed to efficiently remove and separate materials. Equipment from Turf Reclamation Solutions is specifically designed to remove turf infill from fields in a way that preserves the base and separates the infill from the turf. Take a look at this video to see their process in action.

The existing infill can be reused and/or be incorporated into the stone base via a patent-pending process to increase drainage rates. For a more comprehensively sustainable infill solution, choose Envirofill, which is a 100% reusable turf infill, or Safeshell, a completely organic turf infill.

So what becomes of the old turf field?

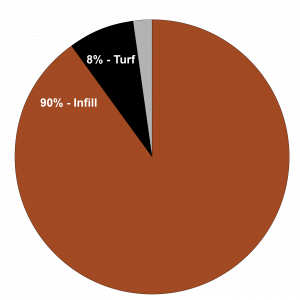

Old synthetic turf fields will be recycled into a new field shock pad called NXTPlay. Once the turf is separated from the other field components onsite, it is sent back to a facility owned and operated by Shaw Industries in Dalton, GA (about 380 miles from Motz’s headquarters in Cincinnati). Shaw’s facility processes the used turf material into new shock absorption pads, which are then installed under fields to enhance performance and safety.

The turf fibers and woven backing are processed into smaller pieces with a binder, which is then used in a proprietary formulation to create the new shock pad containing approximately 50% recycled turf content and 80% total recycled content.

This new pad is a Cradle to Cradle certified productTM. That means the raw materials have been assessed to avoid the use of harmful chemicals and the product can be safely recycled into a new product at the end of its useful life. And thankfully, the cost of going green is budget-friendly. All of this can be accomplished for about $0.10 per square foot.

A chain of custody is important to ensure that the material has left the field and made it to the correct destination. Motz is able to provide a chain of custody from the field to the Shaw Industries processing facility. From there, the material is blended with material from other fields to create the NXTPlay performance shock pad.

Measuring the impact of synthetic turf recycling

One field of turf represents about 20 tons of plastic material. According to Waste Management, one ton of recycled plastic saves 16.3 gallons of oil. Therefore, one recycled field saves 326 gallons of oil.

The responsible handling of artificial turf field recycling and replacement is the result of a well-coordinated response from many crucial players, including field owners, designers, contractors, and manufacturers. Together Shaw Industries and Motz offer field owners a complete, turnkey service that’s economical and environmentally responsible.

Contact Motz to learn more about turf recycling.

Learn more about Motz’s suggested specifications

The Synthetic Turf System Vendor shall have the capability to remove, reclaim and recycle the synthetic turf system at the end of its useful life. The Synthetic Turf System Vendor must provide documentation outlining their product lifetime recycle/reuse program that is currently in place. A minimum of 5 fields must have been used in this process. All materials must demonstrate the capability to reuse in a product that employs a cradle-to-cradle design. Reuse or other diversion plans that do not include the production of a new and useful product will not be considered.

Similar Blogs